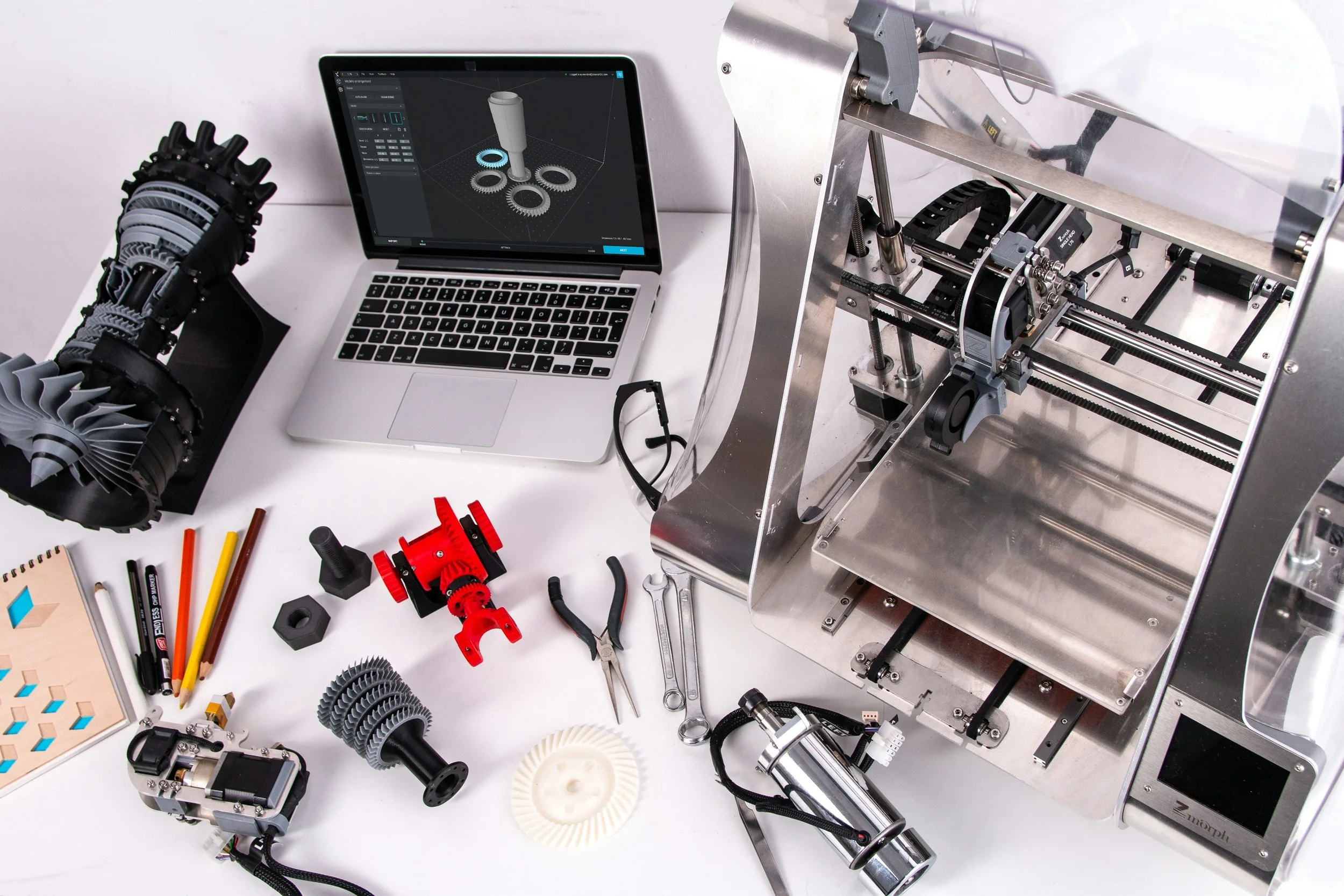

TRANSFORM CHALLENGES INTO OPPORTUNITIES:

Solving manufacturing problems at the intersection of design, process, and people.

Organizations don’t struggle because they lack Lean tools. They struggle because systems aren’t designed for problem-solving. Delays, defects, cost overruns, and rework are symptoms of deeper issues—design decisions, process gaps, and cross-functional misalignment.

The KPI Lab helps med-tech and manufacturing organizations diagnose what’s really driving cost, delay, or rework—and guide teams toward solutions that actually stick.

We blend engineering depth with practical, people-centered facilitation to reduce complexity, improve manufacturability, and build internal capability along the way.

What We Do

Design for Manufacturing & Assembly (DFM/A)

We evaluate product and system design through a manufacturability lens—identifying opportunities to simplify assemblies, reduce components, eliminate handling waste, and improve production flow. We translate engineering intent into practical solutions that work on the shop floor.

New Product Introduction (NPI) Support

We support teams early in development to identify risks, streamline design transfer, and ensure alignment across R&D, AME, operations, and supply chain. The result: smoother launch, lower cost, and fewer surprises downstream.

Redesign for Cost

We analyze cost drivers across design, materials, manufacturing, and supply chain to uncover opportunities for cost reduction. Our approach includes VAVE, component consolidation, alternate sourcing strategies, and engineering tradeoff analysis.

On-Site Manufacturing Assessment

We conduct targeted, hands-on assessments to understand how products are currently built—mapping processes, identifying inefficiencies, and evaluating ergonomics, rework loops, test processes, and key bottlenecks. We deliver clear, actionable recommendations aligned to your cost and performance goals.

Cross-Functional Technical Facilitation

Most problems aren’t just technical—they’re cross-functional. We bring R&D, engineering, AME, operations, and supply chain together in structured working sessions that accelerate decision-making, reduce friction, and build ownership.

How We Work

Consultant-Led

We run the assessment, conduct the analysis, and deliver a detailed cost-reduction or redesign roadmap.

Team-Based

We guide your internal technical teams through structured problem-solving, ensuring buy-in, capability growth, and long-term ownership.

Hybrid

We combine our technical depth with your team’s context and bandwidth—ideal when you need expertise but want your team engaged and developing.

Our Technical Background

Our experience spans GE Healthcare, and high-growth med-tech environments across R&D, development engineering, AME, and operations.

We bring:

Deep technical understanding across complex assemblies

Practical knowledge of manufacturing realities and process constraints

The ability to surface hidden assumptions and bridge cross-functional gaps

A facilitation style that reduces friction and accelerates alignment

The communication skills to work seamlessly from shop floor to C-suite

If you’re ready to solve your toughest technical and operational challenges, we’re here to help you engineer the systems that make it possible.

Let’s work together to transform your problems into possibilities.